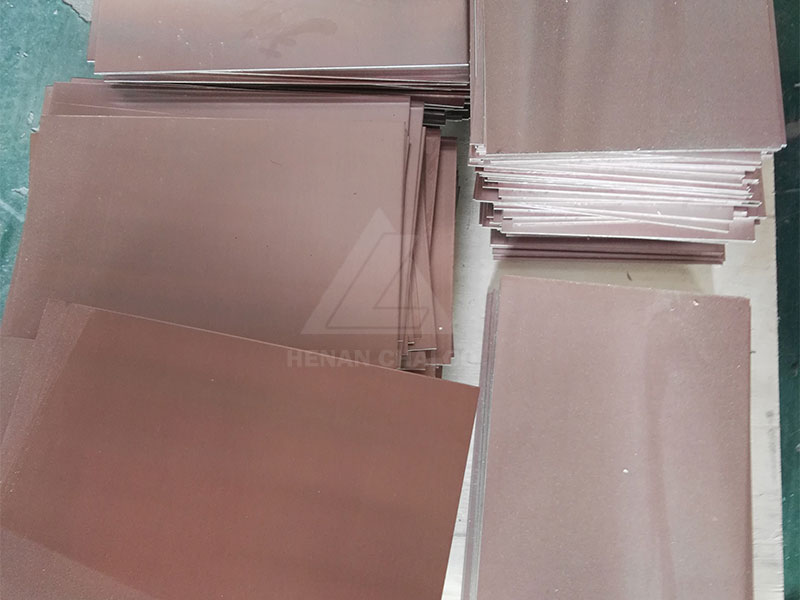

Henan Chalco produces single-sided copper clad aluminum plates sheets, which make full use of the excellent thermal conductivity and heat dissipation physical properties of copper and aluminum metals, rapidly speaking of heat derivation. It is used in COB packaging of high-power LED as an excellent heat dissipation substrate material.

Features:

1. Flat plate, uniform thickness of copper layer, high mechanical strength, extreme cold, extreme heat and no lamination. Extend the service life of the product, and realize the intensive miniaturization design of the same power.

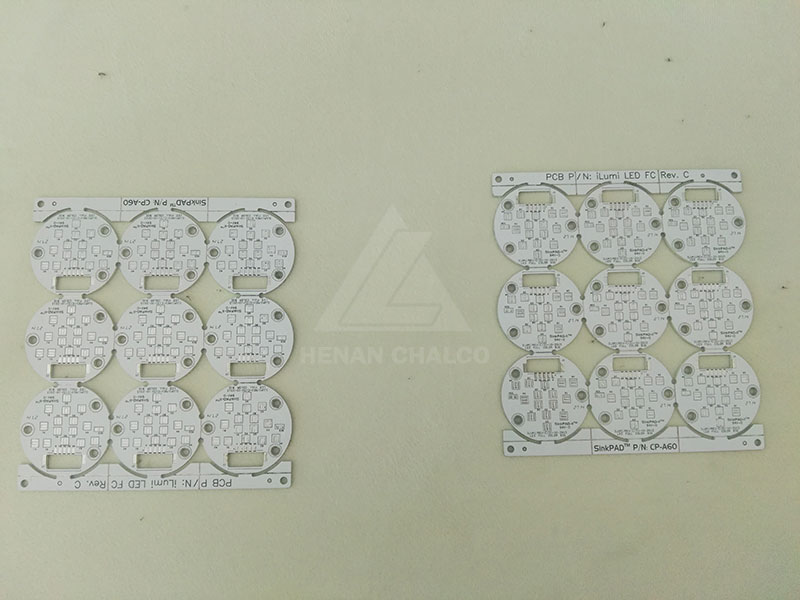

2. LED chips are directly encapsulated on the copper surface. The heat generated by the chips is transmitted directly from copper to the whole surface. Then the chips are dispersed through aluminum. The good thermal conductivity of copper and the heat dissipation performance of aluminum are brought into full play. It is the most ideal DOB subassembly heat dissipation substrate material at present.

| Thickness | Width | Temper | Bonding strength | Copper ratio | Tensile strength | Elongation |

| 0.3-2.0mm | ≤1000mm | H18、H24 | ≥12N/mm | 10%-20% | 130-220MPa | 5-10% |