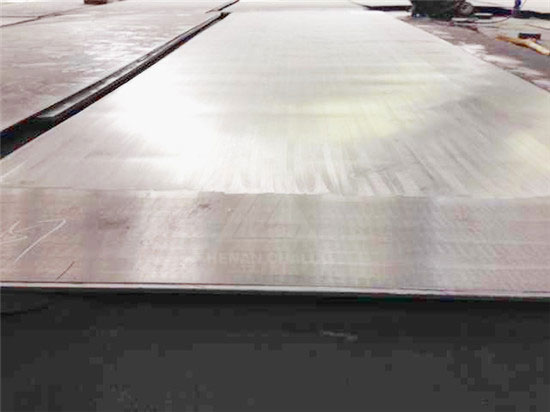

Metal clad plate is a clad material formed by metallurgical bonding of metals with different properties on the interface by various clad technologies. Through proper material selection and reasonable structure design, metal clad plates can greatly improve the thermal expansion, strength, toughness, wear resistance, corrosion resistance, electrical and magnetic properties of single metal materials, and are widely used in petroleum, chemical industry, ship, metallurgy, power, water conservancy, transportation, environmental protection, food, pharmaceuticals and other industrial fields. In addition to its structural and functional characteristics, metal clad plates can also save the use of precious metals and significantly reduce the cost of various equipment materials.

Common metal clad plates are: titanium steel clad plate, copper steel clad plate, titanium-zinc clad plate, titanium-nickel clad plate, nickel steel clad plate, copper-aluminium clad plate, nickel-copper clad plate, etc.

Advantage

Metal clad plate material technology can give full play to the respective advantages of component materials, realize the optimal allocation of material resources of each component, save precious metal materials and achieve performance requirements that single metal can not meet. Taking stainless steel-steel clad plate for pressure vessel as an example, carbon steel (Q245R, Q345R, etc.) for base has good mechanical properties, and stainless steel (304, 316L, etc.) for multilayer has good mechanical properties. Corrosion resistance, which is usually welded together by explosive welding, requires only a few millimeters of high-priced stainless steel, which saves a lot of cost and hardly changes the mechanical properties of the substrate. It can not only replace imports and fill the domestic gap, but also has a wide range of applications, with good economic and social benefits, easy to get support and help from all aspects. For example, the development of stainless steel clad materials has been a high-tech project actively supported and advocated by the National Development and Reform Commission and the Ministry of Science and Technology.

The development potential of traditional metal clad plate has been enhanced due to the functionalization of properties, low cost and wide application range of heterogeneous metal clads. With the strengthening of the implementation of national environmental protection industrial policy, the application of rare metal clad materials in electric power flue gas desulfurization equipment continues to grow. At the same time, the degree of investment localization in chemical industry has been greatly accelerated, which also provides a good development opportunity for the development of rare metal materials.

The support of national industrial policy, high technical barriers and the demand of industrial upgrading provide broad space for the development of the industry. Metal clad plate is a kind of plate with one layer of metal overlaid with another metal, which has achieved the effect of saving resources and reducing costs without reducing the use effect (anti-corrosion performance, mechanical strength, etc.).

How is clad plate made?

I. Direct rolling

Direct rolling is a common method to produce metal clad plates, which can be divided into hot rolling and cold rolling.

a. Hot Rolling clad Method

Hot-rolled clad method is a method of overlapping the clad material and the base material, welding around it, and combining the clad material and the base material by hot-rolling. Under the action of shear deformation force, the contact surface between the two metals is very similar to that of viscous fluid, and tends to be fluid-like. Once the new metal surfaces appear, they will produce adhesion and friction behavior, which is beneficial to the metal fixation between the contact surfaces. Based on the fixed point (or core), stable thermal diffusion will be formed under the condition of high temperature thermal activation, thus realizing the welding bonding between metals.

b. Cold rolling clad method

Usually, people call equal roll diameter and equal roll speed cold rolling clad method for short cold rolling clad method. In the 1950s, the United States began to study the three-step production process of "surface treatment + cold rolling clad + diffusion annealing". Compared with the hot rolling process, the first pass deformation of cold rolling process is larger, usually up to 60%-70%, or even higher. By means of large reduction, cold-rolled overlapping two or more layers of metal can produce atom bonding or mortise-and-tenon chimerism, which is then strengthened by diffusion annealing.

2. Explosive billet rolling

The explosive billet rolling method is a production method that the required base and clad materials are welded by explosion and then rolled to the required size of clad strip by hot rolling mill. This method is a new combined technology which combines the advantages of explosive recombination technology and rolling technology. Its advantages are as follows:

(1) The quality of the bonding zone of two or three layers of metal clad plates is guaranteed by explosive bonding.

(2) The product has high dimensional accuracy and good surface quality.

(3) Increased production flexibility, easy to promote.

3. Casting-rolling clad Method

The process of casting-rolling clad method is as follows: two steel plates are overlapped, the inner layer is coated with stripping agent, welded around them and placed in the casting mould containing liquid metal, and the liquid metal is solidified before blooming. Finally, the welded edge is cut off, and the clad plate is obtained. Higher clad strength can be achieved at appropriate temperature and pressure. This method has the advantages of simple process and low cost, and can be used in batch production.

Chalco clad adopts hot rolling clad method and explosive welding method, to make different type of clad plates, and serve different filed clients, such as in anti-corrosion, pressure vessel manufacturing, electrical construction, petrochemical, pharmaceutical, light industry, automobile and other industries.