The current aluminum copper composite guide

The core components of the body are generally made of copper and aluminum. Copper is generally attached to the surface and aluminum is inside. Modern manufacturing techniques are combined to form a copper clad aluminum material that meets a variety of manufacturing requirements.

The performance of this composite conductor material is as follows:

First of all, in terms of conductivity, compared with other conductor materials, this composite conductor material has very low requirements for the intervention of external means, has a good conductive effect, and has a good comparative advantage. The second is that its weight is very light. Compared with traditional metal conductors, the quality of traditional metal conductor copper is twice the mass of the composite conductor. This can provide greater quality for high-tech fields with higher quality requirements. Effectiveness, currently in the aerospace, rail transit, and microelectronics fields, has achieved a relatively wide range of applications, which can greatly improve the efficiency of the use of materials and increase the cost-effectiveness. Finally, from the perspective of economic cost, aluminum copper is the most common conductor material on the market, especially the relatively cheap aluminum raw materials, which can greatly reduce the manufacturing cost of the composite conductor. This is also the broad market prospect of copper-aluminum composite conductors. important reason.

copper clad aluminum material used

The materials are mainly divided into the following three categories: The first type is a round solid conductor, that is, copper-clad aluminum wire. The conductor standard has been upgraded from the 2000 electronic industry standard to the 2012 national standard. According to the provisions of the coaxial communication cable standard, this type is used for the inner conductor of the radio frequency coaxial cable with a smaller diameter. At the same time, people also use copper-clad aluminum wire for power frequency wire and cable conductors, and develop a variety of electrical products such as building wiring, power cables, flame-retardant cables, control cables, and electric welding machine cables, which are being produced and used. Valuable experience has been accumulated in practice.

However, the application of copper-clad aluminum wire in industrial frequency cable products has not yet formulated corresponding standards.

allow.

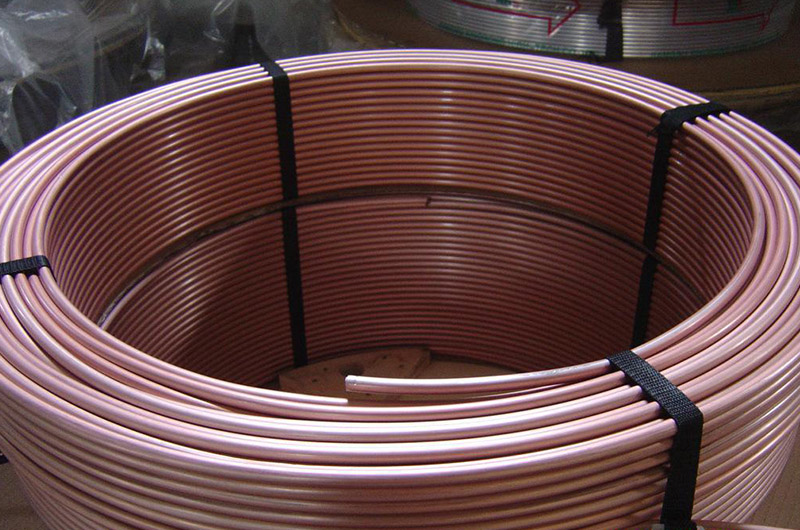

The second type is a tubular conductor, that is, a copper-clad aluminum tube, which is mainly used for the inner conductor of the radio frequency coaxial cable with a relatively thick diameter (φ7.00mm~φ13.10mm). The use of copper pipes was stipulated in the telecommunications industry standards issued in the past. In the telecommunications industry standard, copper-clad aluminum tubes are used as inner conductors. In recent years, China has promulgated the national standard GB/T 33952-2017 "Copper Clad Aluminum Tube", which provides a reliable basis for the production and application of thicker radio frequency coaxial cables. The third type is rectangular conductors, which are mainly copper-aluminum busbars used in the fields of electric control and power distribution equipment. Copper-aluminum busbars are conductor materials with large cross-sections and large currents, which require high performance and reliability, and their production equipment and processes are also complicated.

2.2 Performance of copper-aluminum composite conductor

The performance of copper clad aluminum is closely related to its own properties. Due to the characteristics of copper and aluminum itself, compared with other conductor materials, the material of copper clad aluminum material has strong stability. This kind of stability is an effective conclusion drawn after many stability experiments, and it is also a conclusion drawn from many engineering experiences. This kind of stability helps the composite conductor to achieve large-scale and wide application. Secondly, from the perspective of the composition of the conductor, since aluminum is a lighter, excellent conductor material among metals, compared with copper conductors, this material itself reduces a lot of weight, and the composite conductor can save half of the weight. This kind of performance characteristic is suitable for high-tech fields with high energy consumption requirements.

It has strong applicability and has broad prospects for aviation, transportation and other fields.

The application of copper clad aluminum materials has gained a lot of application experience in engineering practice. Practice has proved that copper clad aluminum materials can achieve effective applications under most environmental conditions. Through a large number of scientific research institutes, enterprises and other institutions on the new research of the composite conductor, the copper clad aluminum has realized the application of new functions in the electric power, railway transformer and other facilities. Through the improvement of various processing techniques, the manufacturing environment is changed during the manufacturing process to make its performance more stable and its quality more suitable for diversified working environments. Through the influence of the use form of copper and aluminum bars, the use of the composite conductor in the field of communication cables has also been effective.

Effective expansion, the composite conductor material in application, in addition to the characteristics of light material, stable performance, etc., the composite conductor also has the characteristics of corrosion resistance, this feature has a unique advantage for the complex and harsh application environment of wire and cable . At the same time, the conductor material has proved through experiments and practice to effectively prevent electromagnetic interference. The current applications of copper clad aluminum materials also include the use in the automotive field and cables. As the most important means of transportation for people to travel in today's society, people are pursuing higher and higher performance requirements and cost-effectiveness of automobiles, and new changes in automobile materials and manufacturing processes are constantly taking place. In the application of automotive wiring harness, it can be seen that the composite conductor also has very obvious advantages. The traditional automotive wiring harness lacks accuracy and often has problems such as jumpers. After the use of copper-aluminum composite conductors, it can effectively solve the jumpers. The problem. It satisfies the precise layout requirements of the automobile production process, and can greatly improve the crimping performance at the same time. Because the copper clad aluminum itself has strong stability, the cable made of the composite conductor can meet engineering requirements such as large projects and long-term use. The safety and stability of the conductor itself has improved the safety of the cable. Very high guarantee.

The development prospects of copper clad aluminum materials are very broad. With the increasing pressure for the transformation and upgrading of China's manufacturing industry, China's economy has entered a stage of new normal development, and economic transformation requires the emergence of more new technologies and newly manufactured products. Only by continuously improving the quality and technological level of China's industrial manufacturing can China's manufacturing industry continue to move forward on a more healthy and stable road. At present, the development of China's manufacturing industry is vigorously implementing the strategy of going global. China's status as a world factory is becoming more and more consolidated. The next step in the development of China's manufacturing industry is towards quality development, and towards high-end manufacturing as the new development goal. In this context, if China’s high-end manufacturing industry wants to make a breakthrough, it needs to make breakthroughs and innovations in manufacturing technology and material processes. The emergence of new materials and new processes represented by copper-aluminum composite conductors can greatly improve The manufacturing level of China's manufacturing industry enhances the overall competitiveness of China's manufacturing industry.

With the continuous strengthening of the application and experimentation of copper-aluminum composite conductors in China, copper clad aluminum materials will expand in more and more fields, gradually moving from aerospace, rail transit, and electric power to microelectronics, new energy, More and more new fields such as biochemical engineering are being expanded. Take the automobile industry as a representative. At present, many joint venture automobile manufacturers or domestic automobile manufacturers in China have begun to increase investment in research and development of production materials. Many automobile manufacturers have used copper clad aluminum materials as important materials. Research projects for public relations. With more and more investment in scientific research, especially the country's emphasis on material technology, the application and manufacturing process of copper-aluminum composite conductors will be more optimized. The production cost of copper clad aluminum materials will continue to decrease, and the quality and stability of production will be more adequately guaranteed, which is more conducive to the performance of new composite conductor materials.