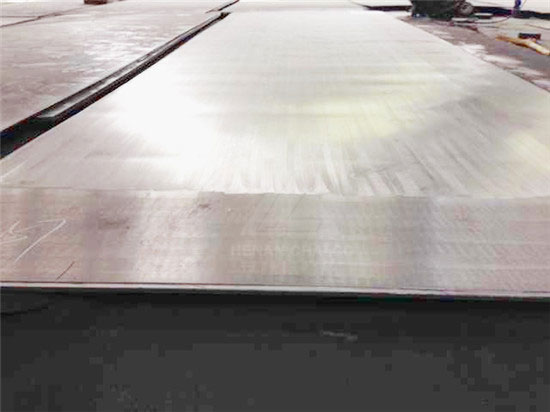

In order to save titanium resources and reduce costs, and to promote this new metal material in civil industry, Ti Titanium clad steel plate is applied.

Ti Titanium clad steel plates are widely used in petrochemical industry and pressure vessels. Using this kind of structural material can not only reduce the cost of related equipment, but also overcome many shortcomings of single titanium equipment and lining structure in this field.

The equipment made of Ti Titanium clad steel plate has corrosion resistance in inner layer and strength in outer layer. The two layers are connected together, which has good thermal conductivity and the ability to overcome thermal stress, thermal fatigue, pressure difference and other loads. It can work under more harsh conditions. Therefore, Ti Titanium clad steel plate has become an indispensable structural material for modern chemical industry and pressure vessel industry.

Ti Titanium clad steel plates manufactured by Chalco Clad are widely used in power plant chimneys, pressure vessels, chemical storage tanks, etc.