The aluminum to stainless transition joints prepared by Chalco aluminum by the rolling compound method, the microscopic morphology of the composite interface is observed by scanning electron microscope, and the tensile properties and deep drawing properties of the composite plate are tested through the tensile test and the cupping test. Good, widely recognized and accepted by customers all over the world.

First, high-pressure water mist is used to remove dust and other debris on the surface of the stainless steel plate and aluminum plate to be composited, the main transmission steel brush roller is used for hairdressing, and then the high-pressure water mist nozzle and nylon brush roller are used to clean the surface treatment method, and the microscopic shape of the composite interface The intercalation of the two metals in the appearance is obvious. At the same time, the tensile strength, yield strength and elongation have been improved to a certain extent; the heating temperature is 430℃, the rolling speed is 7m/min, and the reduction is 27% When the composite plate has the best comprehensive mechanical properties, the bonding strength is relatively high; after the temperature is 400 ℃, the holding time is 1.5h, the interface micro morphology of the diffusion annealing treatment after rolling has obvious interlocking between the two metals The phenomenon, the waves are small and irregular, no intermetallic compounds are formed, and the combination is relatively tight. In addition, after the composite board is annealed, the tensile strength and yield strength have decreased. Although the elongation and cupping value have increased, the range is not large. The tensile test was carried out on the composite plate and each layer component prepared according to the optimal process route to prepare tensile specimens to test its mechanical properties. The results show that the tensile strength and yield strength of the composite plate are better than those of the stainless steel layer. Decrease, but a significant increase compared to the pure aluminum layer; the forming performance is lower than that of the stainless steel layer and the pure aluminum layer; when it is 45° to the rolling direction, the degree of work hardening is the smallest, which is more likely to occur during stamping. Lug" phenomenon. Finally, DEFORM software was used to verify the rolling process with different reductions. The equivalent stress field, equivalent strain field, and interface bonding strength were analyzed, and the simulation results were analyzed and the reduction was 27. When %%, the deformation coordination of the bonding interface of the composite board is the best, and the bonding strength is also the highest.

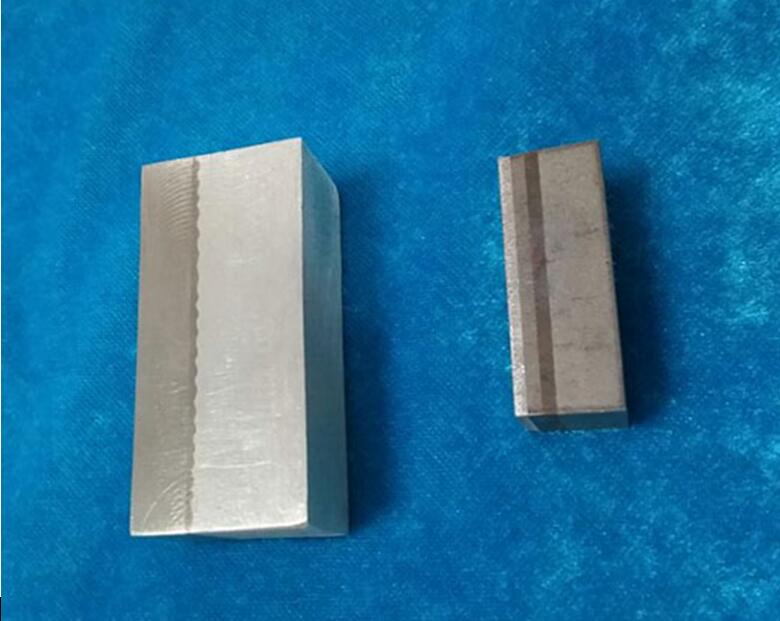

Aluminum to stainless transition joints, one side is stainless steel, the other side is aluminum alloy, the two can be compounded in multiple ratios such as 1:2 or 1:3, which not only retains the strength and toughness of stainless steel, but also takes into account that the AL is relatively light and easy to process It has the characteristics of good thermal conductivity, high hardness and light weight without delamination during stretching and bending. It is widely used in cooking utensils, mobile phone cases, building materials, medical, aviation and other fields.