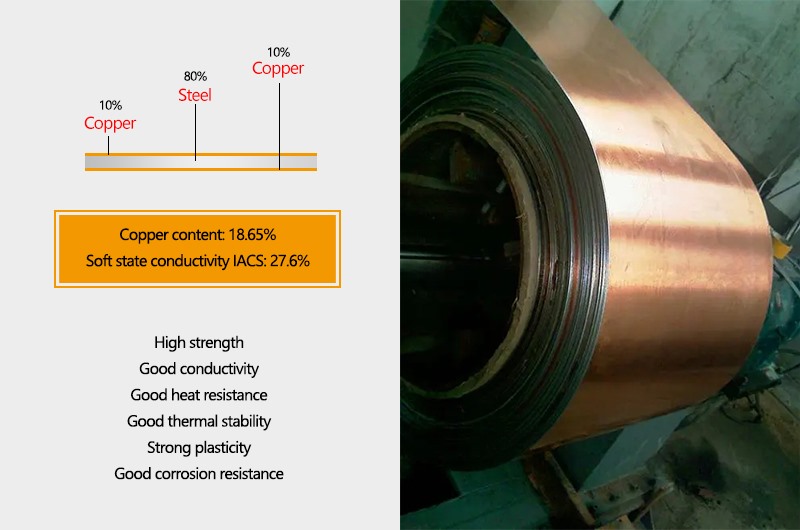

In the recently released CEEIA b222-2013 copper steel composite sheet and strip for electrical engineering, when the coverage rate of copper steel composite sheet and strip is 10 / 80 / 10% (copper content 18.65%), the soft conductivity IACS reaches 27.6%, which is higher than the conductivity index of copper alloy H65. Therefore, copper clad steel sheet and strip is a typical example of skillfully applying the skin effect of current and electron movement to conductive materials. Its surface coated with copper can meet the basic needs of conductivity, and the middle base steel can meet the strength needs of support. The skin effect of alternating current explains the credibility of copper steel composite used in electrical connector products from the technical point of view of current and electron movement.

Therefore, the research, development and application of new polymetallic composites are becoming more and more important. It also gave birth to the production and development of copper steel bimetallic composite plate and strip materials. The copper clad steel sheet and strip developed and produced by Chalco aluminum is just a new metal composite product in the field of domestic new materials developed to meet the needs of the market.

In the industries of electronic parts, low-voltage appliances, relays, circuit breakers and electrical connectors, copper clad steel sheet and strip are complementary to the application field of pure copper. The use of copper steel composite plate and strip material can not only save costs for downstream enterprises and end consumers, but also save a lot of valuable copper resources for the country. Copper steel composite plate and strip material combines the characteristics of two metals. It has the characteristics of copper metal corrosion resistance, formability, conductivity and beautiful surface. It also has good strength of steel. Its good comprehensive performance is unmatched by single metal copper or steel. It is a new material with excellent functionality in the field of electrical connectors of electronics, electrical appliances and automotive electrical appliances.

Application of copper in electronic industry

Copper and copper alloys with medium and high strength have good conductivity, processing, brazing and corrosion resistance. At present, they are used as lead frames in microelectronics and semiconductor integrated circuits in the electronic industry. They are both lead and support framework in integrated packaging circuits. With the development of the Internet, copper is still the preferred carrier for end-users

Body; Moreover, various local networks, computers and other hardware, especially connectors, need to use copper and copper alloy.

Because the current when alternating current passes through the conductor will tend to the skin effect flowing on the conductor surface, when the current is conducted in the conductor at a higher frequency, it will gather on the conductor surface instead of evenly distributed in the cross-sectional area of the whole conductor. The higher the frequency, the more significant the skin effect is. Therefore, most of the current is transmitted on the surface of conductive materials. Traditionally

The conductive tape material used is copper, which has excellent conductivity. If it only meets the needs of conductivity, the cross-sectional area of the conductive material does not need to be large; However, generally, the conductive connector also needs to have a certain strength, so the thickness of the copper strip is determined according to the conductive demand. At the same time, the strength of copper will be relatively reduced at high temperature. In order to support the needs, the cross-sectional area of the connector used is much larger than that required for conductivity.

Copper clad steel sheet and strip has better mechanical properties than copper and copper alloy. At the same time, it has the appearance and texture of pure copper and good electrical properties. Compared with single metal materials, it also has the comprehensive characteristics of high strength, good conductivity, heat resistance, thermal stability, plasticity, corrosion resistance and beautiful surface. The coverage rate of pure copper coating of the product is less than 20%, and the conductivity IACS is more than 20%, which fills the gap that the coverage rate of pure copper coating of copper steel composite plate and strip products is ≤ 20%. The product adopts diffusion annealing technology to realize the metallurgical recombination of copper steel interface and ensure the stability of product performance; The overall technology has reached the domestic leading level.